Stoke Space secures funding to ensure rocket development in the Basin

MOSES LAKE — Stoke Space, an aerospace company developing the world’s first 100% reusable medium-lift rocket, announced in January that it has raised $260 million in funding to push toward continuing growth of the company and development of its rocket. The investment more than doubles the company’s total funding, bringing it to $480 million.

“We deeply appreciate the confidence investors have placed in Stoke and our mission,” said Andy Lapsa, CEO and co-founder of Stoke Space. “This new investment validates our progress and enables us to accelerate the development of technologies that will redefine access to and from space.”

That development is happening in an Eastern Washington city with a long history of aeronautic and aerospace development – Moses Lake. The funding comes after Stoke had a successful vertical test firing at its Moses Lake facility.

Vice President and Moses Lake Test Site and Operations Director Katherine Cruz said setting the development of the rocket’s engines in Moses Lake made simple sense. The land, expertise and transportation to safely develop and transport the new first-stage Zenith engine was in the right spot. Additionally, local partners like Norco, which provides the special fuel needed to test the rocket, construction companies, Big Bend Community College, the Port of Moses Lake and others have made establishing the development and test site convenient and economical.

“We have an employee on our team who came from Big Bend Community College. We hired him right out of school. He’s excellent. He learned all of the skills that we use here just right down the road, and he has already referred me to a lot of his classmates,” Cruz said.

John Taylor, a public relations consultant for Stoke, said it makes sense for the company to hire locally. Not only does it establish Stoke as part of the community, but the people hired locally consider the Columbia Basin home, so are less likely to want to leave for more metropolitan areas.

Cruz said the ability to work on the development of a new rocket is invigorating. She had already been working in the industry, working for Blue Origin, testing engines, which she said she loved.

“I mean, it’s an adrenaline rush every time the engine fires, and it’s quite an addicting feeling. So, I was already doing something I never even dreamed of doing,” Cruz said.

Then she got a call from Lapsa, asking her if she was interested in founding a test site for Stoke. She spoke with the Stoke team, and decided she was ready for a new challenge.

“I wasn’t just going to run a test stand, but get to develop a test site and learn new skills and be challenged in new ways with that,” she said.

Reusable second-stage and medium payload rockets don’t have a long history. While some companies are working on reusable rockets of other types, this would be a new niche in the industry that Cruz and her team would be able to put their stamps on, Cruz said Lapsa pointed out to her. Further, his description of the engine concept and how it needed to operate intrigued her. That opportunity to innovate drew her in and she signed on.

“I just want to be a part of something novel, right? And I don’t want to just keep participating in the industry at the status quo, but I was like, ‘Yeah, why not try to do something crazy and new and just see where it goes,’” Cruz said. “And so, it’s a cool thing to be able to see the first engine start. It took it forever to get it to start ... but when it finally did, you just see your intent come to life. That’s the reality of it all, and we’ve seen a lot of progress for the past few years. It’s been pretty incredible to experience.”

The facility in Moses Lake has evolved quite a bit since Cruz signed on and the team got to work. There was initially just a bare patch of land that had the right setup to be able to become a rocket engine development and test site. Since then, the company has built an office building with attached industrial workshop, installed multiple insulated containers to hold rocket fuel – the stuff is chilly at -420 degrees Fahrenheit – a horizontal engine testing mount and another, newer building that can test two vertically mounted engines at the same time.

Safety for the Stoke team and the community is built in with the rockets being test fired in a stationary manner and the staff are in a command center a few hundred feet away, measuring engine test results from a distance.

While the company doesn’t have a huge workforce in Moses Lake, they are contributing to the economy and expecting to grow, Cruz said. The company purchases the fuel from Norco, had local contractors develop the site, purchases fuel from Norco and, gets piece parts from local shops as well.

“Home Depot, primarily,” Cruz said. “We’re going to Home Depot every other day.”

The new funding helps to secure the Moses Lake facility’s success. The engines being developed in the Columbia Basin will be installed on rockets that will be sent to Cape Canaveral, according to a press release from Stoke. The funding will be used to complete the construction of Launch Complex 14 at the Cape Canaveral Space Force Station in Florida. That launch site will be dedicated to Stoke’s Nova launch vehicle which the engines will go into.

The innovation will push both the industry and its implications forward, Lapsa said.

“Rapid and reliable reuse of a rocket’s upper stage is the last big challenge to solve before mobility to and from space becomes akin to other forms of transportation,” said Lapsa. “It represents a significant inflection in the space economy, and in turn opens the door to an incredible set of business opportunities that make life more vibrant on and off Earth.”

Katherine Cruz, Stoke Space VP and Moses Lake test site and operations director, laughs while explaining how the aerospace development company’s new vertical test site functions during a media tour on Jan. 24. Cruz said she loves her job which gives her the opportunity to be on the bleeding edge of rocket development.

Katherine Cruz, Stoke Space VP and Moses Lake test site and operations director, laughs while explaining how the aerospace development company’s new vertical test site functions during a media tour on Jan. 24. Cruz said she loves her job which gives her the opportunity to be on the bleeding edge of rocket development.R. HANS MILLER/BASIN BUSINESS JOURNAL

Force from the rockets undergoing vertical testing is diverted using a series of pipes that divert it sideways and across a cement pad. The first of two vertical test fixtures is complete with this photo being taken from the opposite side where another fixture is being installed.

Force from the rockets undergoing vertical testing is diverted using a series of pipes that divert it sideways and across a cement pad. The first of two vertical test fixtures is complete with this photo being taken from the opposite side where another fixture is being installed.R. HANS MILLER/BASIN BUSINESS JOURNAL

4916891

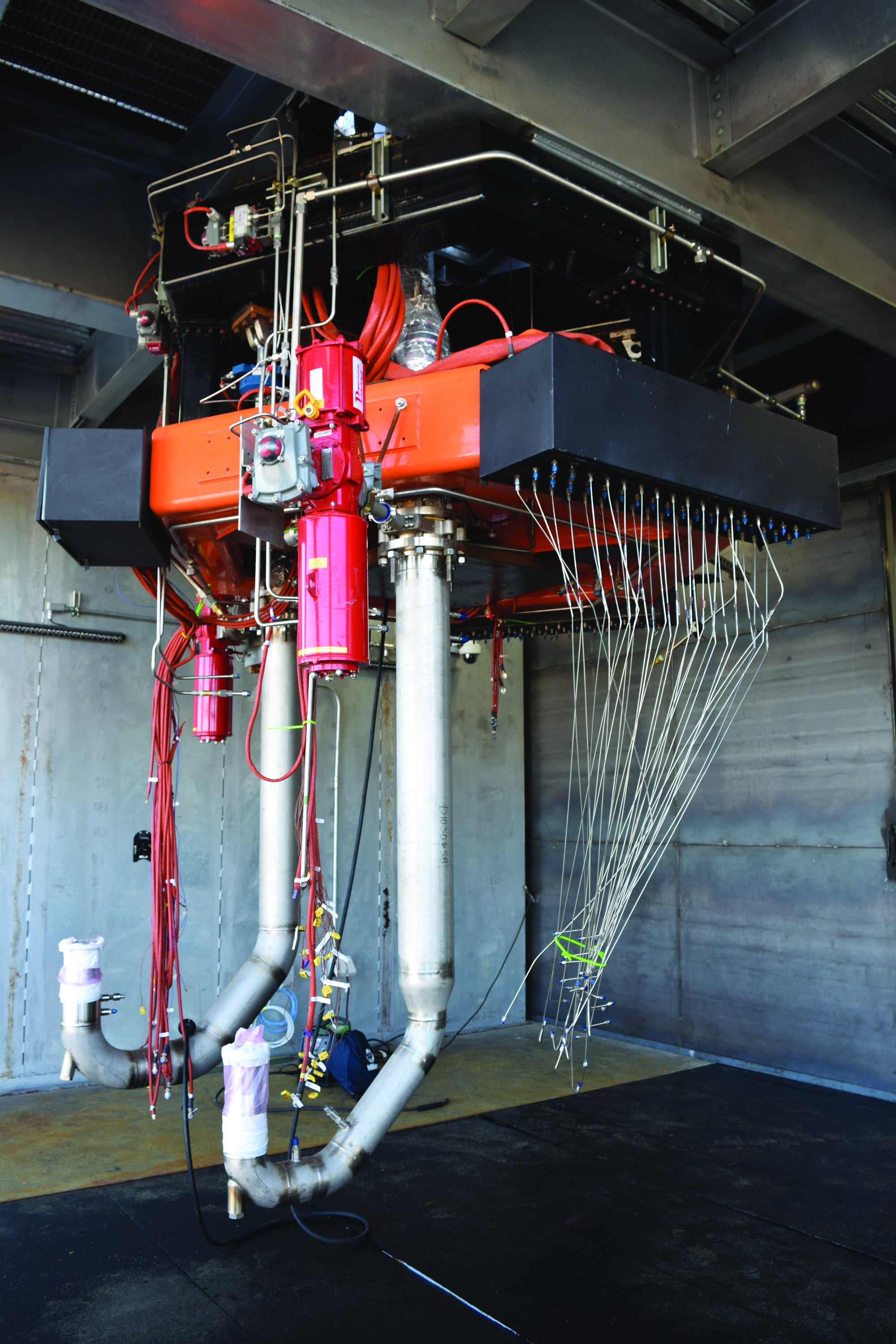

Katherine Cruz explains how the horizontal rocket test platform works and what it’s used for. The various tubes connect to the rocket to provide fuel and cameras and sensors provide feedback to the development team on a variety of factors associated with engine performance.

Katherine Cruz explains how the horizontal rocket test platform works and what it’s used for. The various tubes connect to the rocket to provide fuel and cameras and sensors provide feedback to the development team on a variety of factors associated with engine performance.R. HANS MILLER/BASIN BUSINESS JOURNAL